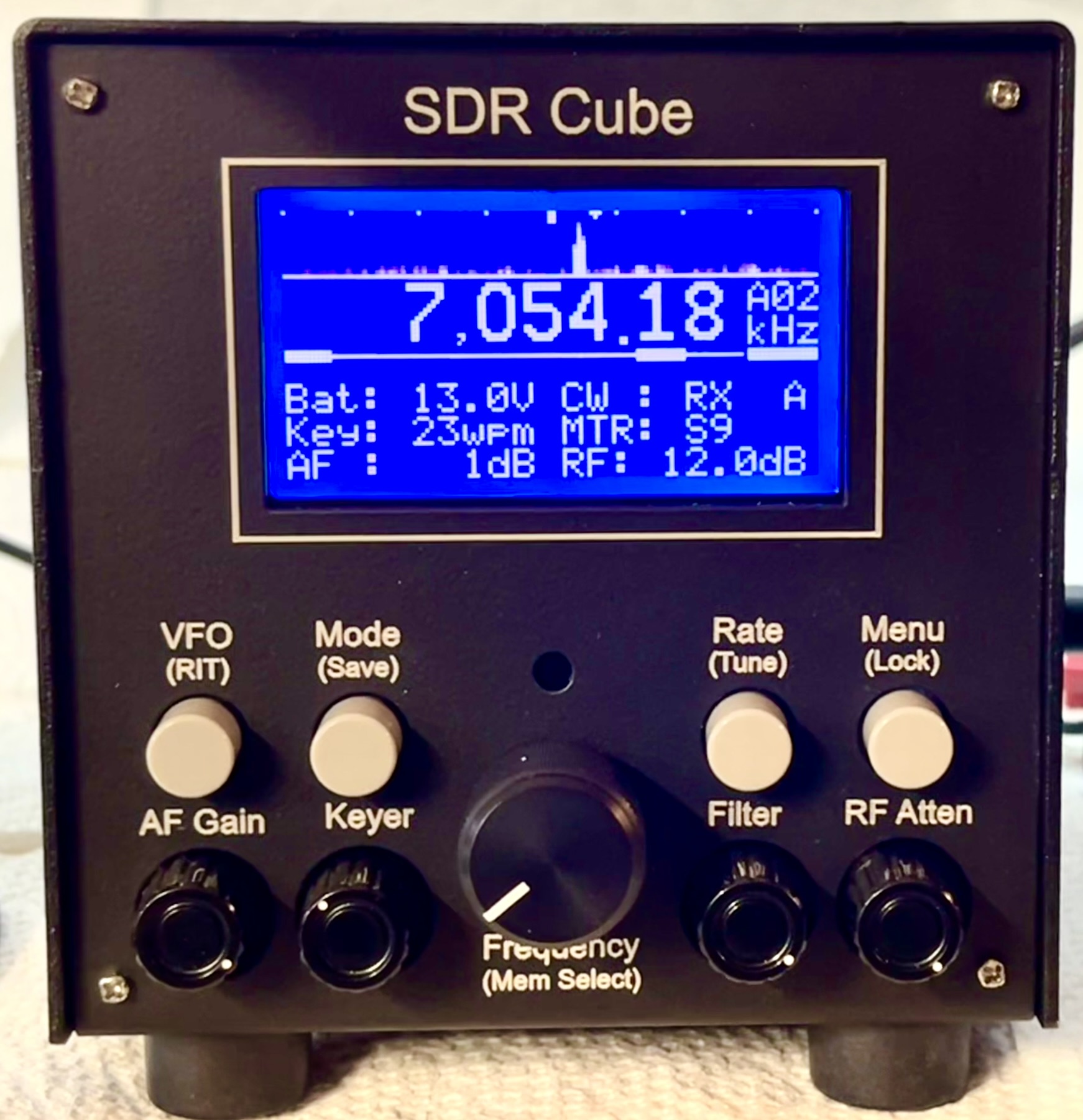

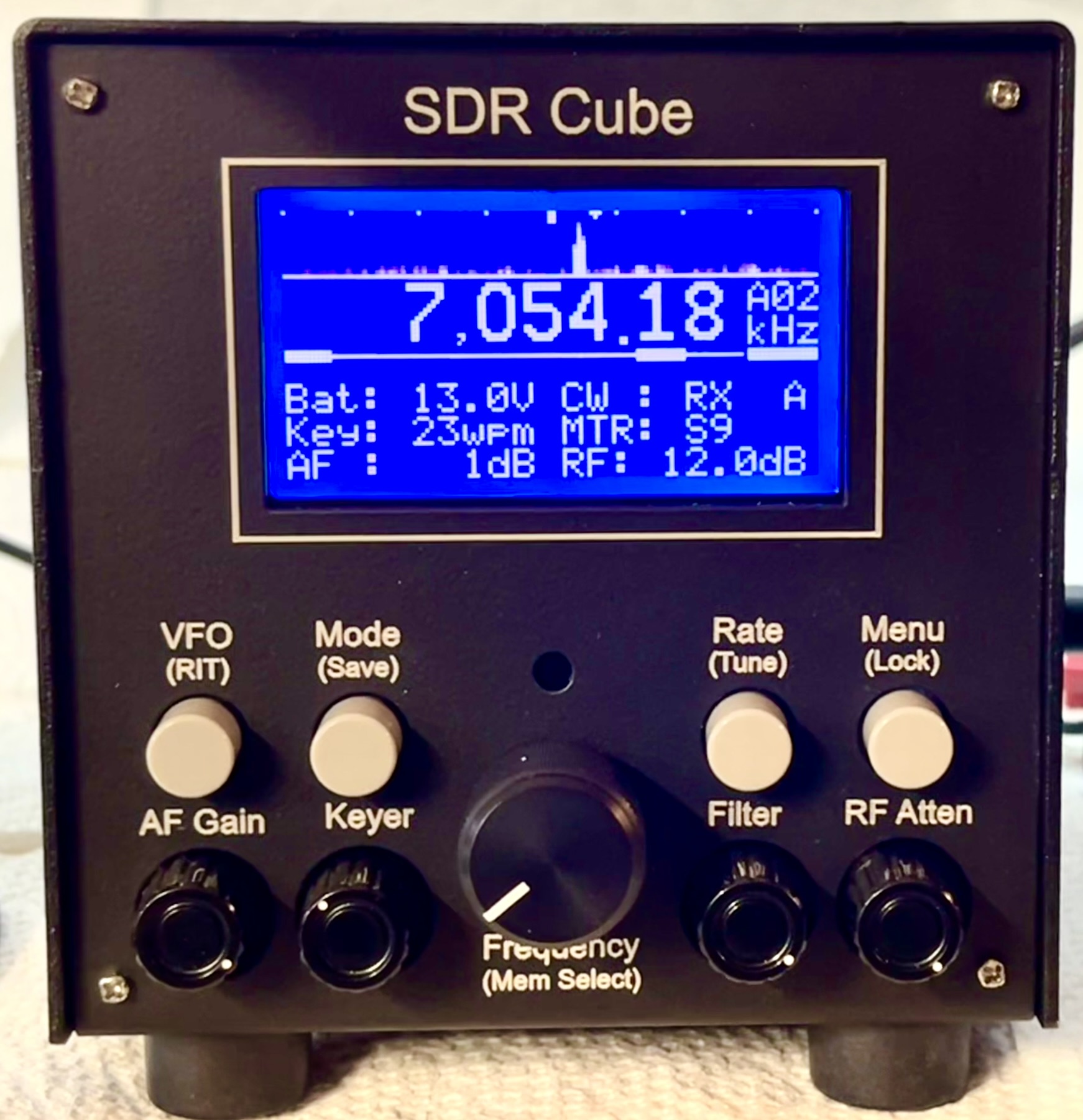

The Goal

The goal of this section is to assemble all

completed SDR Cube boards and optional boards into the main Enclosure. The

available space starts getting a little tight, so please be sure to follow the

steps recommended on this page ... it works pretty well this way.

STEP 1:

Straighten the front & rear panels of the chassis.

Take the main Enclosure chassis and press outward on

the front and rear panels to make sure they are at 90 degrees to the floor of

the chassis. This will help the DSP board fit properly later on this page.

STEP 2:

Install the Controls board behind the front panel

Use the four remaining #2-56 filister screws to

attach the Controls board as shown below.

STEP 3: Attach

the SR-Base standoffs to the sub-chassis

Remove the four standoffs from the SR-Base assembly

and attach them into the sub-chassis as shown below using the four remaining

4-40 screws from the SR-Base kit assembly process. This will enable you to

easily attach the SR-Base later on this page.

STEP 4:

Attach the Internal cables to the DSP board

Using the

Cable Interconnect Diagram as a guide (having it printed out and with

you on the bench would be most helpful), attach the four Internal Cables to the

DSP board. Be sure to ensure that pin 1 of the cable (red heat shrink) is

oriented on pin 1 of the DSP board connector.

STEP 5:

Feed Cables through bottom access holes in sub-chassis

Feed cable #3 though the right access hole in the

sub-chassis, as shown below. Then take the SR-Base power cable (#6) and

feed it through the other access hole, as also shown.

STEP 6:

Attach the I/O board to the sub-chassis & connect the SR-Base power cable #6

Using the four remaining #4-40 screws from the I/O

board kit, attach the I/O board to the sub-chassis as shown in the photo below.

With all eight screws still loose in the standoffs, bias the I/O board toward

the rear of the enclosure in order to have the I/O board edge connectors

protruding as far as possible through the hole in the rear panel. Then

while still applying the boas pressure with one hand, tighten down the eight

screws to hold the I/O board firmly in this optimal position. This action

will ensure that 1/8" stereo plugs connecting to the audio jacks on the board

will sit flush with the jack and be fully inserted.

Next take the tie-wrap supplied in the kit (or in

the Service Pack provided for early kit owners) and attach it in a way that

gently holds down the offboard-protruding voltage regulator onto the

sub-chassis. Insert one end of the tie-wrap through the hole in the

sub-chassis and wrap it around the backside such that it comes back to the

topside through the slot at the lower end of the sub-chassis. Finish

attaching the two ends of the tie-wrap over the regulator and pull "loosely

snug" thus holding the regulator to the chassis. The white pad on the

bottom of the regulator will help cushion the part while being held in place.

If the regulator was mounted as described in the I/O Assembly section, the

regulator will already sit flush with the surface of the sub-chassis when the

I/O board is mounted. The purpose of the tie-wrap is to ensure that there

is no "wiggling" of the regular (from vibration) when the Cube is being

transported.

Lastly for this step, take the loose Cable #6 and connect it to P10 on the I/O board, ensuring

that the red side of the plug is oriented to the right, as shown. (This is

= +12V.) Gently push that connector downward and angle the wires coming

from it at a sharp 90-degree bend, so as to keep the protruding cable as close to

the I/O board as possible. (We'll need that space when mounting the DSP

board.

NOTE: The tie-wrap

hold-down technique is not yet shown in these photos. (They will be

updated shortly.)

STEP 7:

Attach cable #1 (40-wire flat cable) to P2 on the DSP card.

It is much easier to do it at this point, rather

than later.

STEP 8:

Attach other end of Cable #1 to the I/O board

Gently holding the octopus assembly of DSP and

cables in one hand, orient the other end of Cable 1 over the 40-position

pinheader P2 on the I/O board and press it into place with your other hand.

Make sure that the DSP board is oriented on the inside of the lower mounting lip

of the chassis, as you will not be able to get it inside after the flat cable is

in position. Then carefully orient the DSP board's P1 connector in front

of the Controls board J1 connector and gently push from the rear of the DSP

board such that the 40-pos'n pinheader inserts fully into J1. (I say

"gently" and"carefully" because you don't not want to manhandle the DSP board

with its many components sticking up from the surface.)

STEP 9:

Orient the cables as shown

Make sure the flat cable has a curve in it to allow

room for the Cable #4 connector on the DSP board. Route the remaining

cables roughly over the top of the sub-chassis for now. Note how the DSP

board is angled slightly outward - we'll take care of that in a minute.

(This is caused by two things: the slightly non-parallel soldering of the DSP

board connector P1 that plugs into the DSP board, as well as a gentle outward

pushing due to the cables between the DSP and I/O boards.)

STEP 10:

Connect Cable 6 to the SR-Base power connector P2 and screw down the SR-Base

board

Take the loose end of Cable 6 and insert it into the

SR-Base power connector P2, being careful to orient the connector such that the

red shrink side is on the left, as shown below. (Again, a reminder that

you will probably want to be using a longer Cable #6 than what is provided in

the initial kits. A 6" cable provides adequate room for the inward-pointing

P2 connector.)

Attach the SR-Base board to the four standoffs on

the sub-chassis using the four #4-40 phillips head screws.

STEP 11:

Attach the X-LPF board

First ensure that the BNC connector is tight, with

its grounding tab oriented pointing to the top of the enclosure. Take the

X-LPF board assembly created in a previous section, and if not already done,

scrape the soldermask away from the main mounting hole so as to expose the

underlying copper for soldering, as shown below. Then mount the X-LPF

board assembly on the BNC center conductor post and solder. Bend the BNC

grounding tab tightly upward until it is just meeting the top edge of the X-LPF

board and solder it to the large rectangular ground pad. (The ground tab

will be perpendicular to the top edge of the X-LPF board and even with the

board. Use a good amount of solder to make a solid connection.) Make

sure the X-LPF board and BNC assembly together are oriented parallel to the side

of the enclosure.

STEP 12:

Connect the remaining cables to the SR-Base assembly.

Insert the RXAMP into position on the SR-Base board

and connect its control Cable #2 to the RXAMP connector P1, carefully

noting the proper location of pin 1 on the connector. (This connector

carries both 5V and ground, so if improperly inserted, some damage can occur.)

Connect Cable #4 (I2C) to P6 on the SR-Base

board at the top-middle location. Pin 1 is oriented to the right.

Connect Cable #5 to P5 on the SR-Base board

at the top-right location. Pin 1 is oriented to the left.

Connect the longer single-wired PTT connector down to P4 on the SR-Base board at

the lower left location.

Connect Cable #3 to P7 on the SR-base board

at the top-left location. Pin 1 is oriented to the left.

Tuck the cables going over the top edge of the

sub-chassis into a convenient access slot, such that when the top cover is

placed on the chassis, the wires will not be pinched.

STEP 13:

Connect Cable #7 from the SR-Base to the X-LPF card on the BNC connector

The RF path from the SR-Base Board to the BNC and

antenna must go through the X-LPF card. As explained elsewhere, the X-LPF

card provides additional filtering when the Cube is used on 80m or 30m.

Cable 7 will connect to the X-LPF card in one of

three ways, depending on the desired band(s) of operation. Additionally,

when set up for 80m or 30m operation, the red shunts (jumpers) should be used in

the indicated positions ...

STEP 14:

Attach 1/4" nylon standoffs to the top and bottom corners of the DSP board

(If not already done earlier during DSP board assembly.)

NOTE: If you reached this step

and have not yet attached the nylon standoffs during the DSP board assembly

phase, you may need to remove the DSP board connector from its mating jack in

the Controls board in order to do this step.

To handle the natural outward bending of the DSP

board mentioned before, two #4 threaded nylon standoffs (from the DSP board kit)

need to be attached to the bottom side of the DSP board at the upper-rear and

lower-rear corners, using the remaining #4-40 screw. These will gently

hold the DSP board away from the chassis mounting lip and the inside of the top

cover when in place. (There is enough force in the DSP board mounting such

that there will be no vibrating or undue stress applied to the board.)

STEP 15:

Attach the top cover, using the #4-40 black flat head screws remaining from the

Man Enclosure assembly step

STEP 16: Attach the main tuning knob

Using the nice black anodized aluminum knob remaining

from the Controls board kitting, position the knob over the shaft of the rotary

encoder on the front panel and tighten down the set screw to hold it in place.

Ensure that the knob is positioned at least 3/16" above the front panel such

that the encoder's pushbutton has sufficient travel to reliably engage.

Some minimal "knob wobble" may be experienced while turning the encoder, and

this is normal even with the better quality encoder and aluminum knob that we

chose for the Cube. This wobble may be reduced, if desired, by carefully

placing shims between the knob and shaft. Some experimentation may be

necessary to achieved desired results.

Congratulations, the SDR Cube is completely

assembled!

Next ... move on to the RF Functional Test section!

Back to Construction Home